2% online discount

Fast delivery, reduced

costs from $250

costs from $250

More than 250,000

products

products

+1 470 777 2649

info.us@analytics-shop.com

Correct crimping of sample bottles in laboratories

Crimping is a daily procedure in most laboratories and is essential for the proper storage of products. Therefore, the correct way to crimp is extremely important. Below is a summary of important facts, tips, product examples, and ways to identify crimping errors. If you have any questions, please do not hesitate to contact our team.

Types of Crimp Applicators

There are two types of crimpers: manual and electronic.

Manual crimpers

- Easy-to-use

- Good chemical resistance of surface coating

- Stainless steel crimping tools suitable for clean rooms use

- Adjustable with set screw

- Product examples: manual crimpers (11 mm), manual crimpers (20 mm)

Electronic crimpers

- Safe, tight and reproducible crimping

- Quick and easy cap removal

- Ergonomic design and the ability to crimp at the touch of a button allow a large number of vials to be processed in a short period of time

- Product examples: electronic crimpers (11 mm), electronic crimpers (20 mm)

Proper Use - Demonstration Video and Troubleshooting Guide

For your reference, here is a video and chart demonstrating the proper use of manual and electronic crimping tools and how to spot errors.

Correct Crimping and Possible Errors

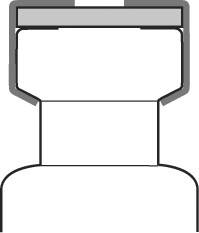

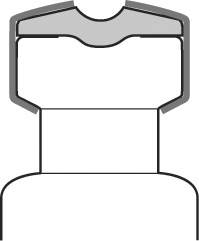

Correct Crimping

- Flat cap surface

- Flat septa surface

- Tight fit of the aluminum cap edge

- Flat and undamaged cap sides

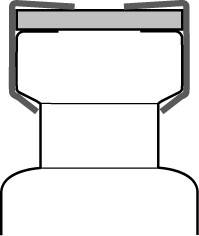

Error 1: Non-adhering aluminum cap edges

- Adjust the crimping pressure using the adjusting screw in the handle

- Adjust the flaring height using the Allen key

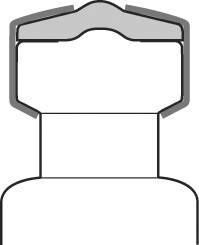

Error 2: curvature of the crimp cap

- Adjust the crimping pressure using the adjusting screw in the handle

- Adjust the crimping height using the Allen key

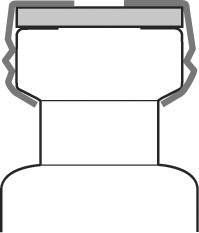

Error 3: deformed cap sides

- Adjust the crimping height using the Allen key

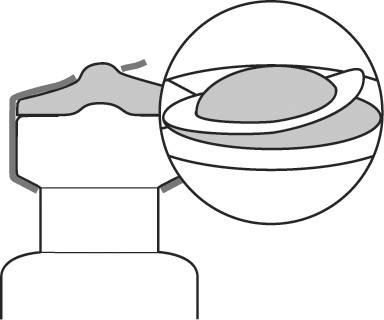

Error 4: Convex-looking seal

- Adjust the flanging pressure using the adjusting screw in the handle

Error 5: Rounded cap edges/curved cap/disc shifts upwards

- It is particularly important not to overcrimp head space caps. If the aluminum is pulled too far under the rolled edge, the retaining webs of the predetermined breaking lines suffer from too much pressure and break open even at low internal bottle pressure (less than 3 bar) or - in the worst case - even tear in two next to the predetermined breaking lines.